The rudder trim knob is poorly moulded and clearly portrays hollow holes left over from the injection process. For those searching for aesthetics, replacement using a real B737 knob is very easy (if you can find a real knob).

The trim needle, at least on my module, is a little lop-sided. As with the ACP module, stray light from the LED backlighting is readily seen around the edge of the panel. Like other SISMO panels, there is no inclusion of a light skirt to stop stray light.

The remainder of the module is aesthetically pleasing.

The rudder trim is one of the modules that is necessary to complete a center pedestal, but unless one is regularly flying with one engine, the module is seldom used. Therefore; this module from SISMO, even with the irregularities, is a reasonably priced alliterative to some of the more expensive counterparts available (provided a replacement knob is used and light skirt is fabricated).

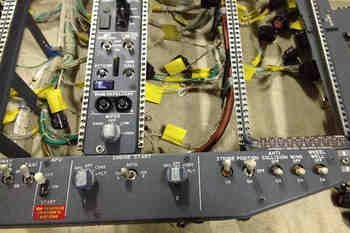

ATC (Transponder) Module

This is one of the better produced modules from SISMO.

The switches and knobs are manufactured to a quality at least equal to what other companies produce. There are no injection holes in the knobs, and turning the frequency knob is very smooth when altering frequencies. The digital read out is crisp, yellow amber in colour, and the tinted window, which falls out easily on the ADF panel, seems to be more secure (although it is the same drop in type). As with the ADF panel, this panel will require you to cut the DZUS rails if you are using an OEM 737 center pedestal.

As a script was never supplied with this module (SISMO did not send it), I cannot provide information to how well it operated.

Reliability and Performance - Software and Modules

Software - SC Pascal Scripts

The modules require SC-Pascal scripts to be installed on the simulator computer.

The basic script is downloaded from the SISMO website. A further customised script is needed to configure the modules to the avionics software package you are using (Sim Avionics, Project magenta, ProSim737, Orion, etc) and FSX. SISMO write the script dedicated to the panels you are using. To activate the panels you run the executable file when you open a flight session.

SC-Pascal scripts are completely new to me, but a little research indicates that the script is used as a software interface between the actual functionality of the various panels, FSUIPC and simulator software.

Once the scripts are installed and configured correctly, a folder is created in which is stored the config.ini file and the executable script. The folder and files can be named and stored anywhere on your computer system. The panels are turned on by activating the executable script (.exe).

As an option, direct access to the script can be made by adding the executable command to the auto start folder of your computer. This option automatically starts the modules when the computer is turned on. The script then runs in stand-by mode until flight simulator is turned on. This option saves time and repetition by not having to turn on the executable file.

As SISMO utilises Ethernet technology, the various IP addresses of the computer (s) you are using need to be correctly configured to allow communication between the computer and the panels. This is basic networking knowledge and is relatively easy to learn.

Once the software is configured, the software and modules should function flawlessly.

Script Problems

I did have some issues with the SC Pascal script freezing when it was initiated. The script also caused some issues which appeared to cause the ADF radios to incorrectly display frequencies. To Juan Ma's credit, he did tweak the script, however, the problems remained.

As I know nothing about SC Pascal scripts, I don't know with certainty whether the problems experienced were caused by a script issue, hardware issue, or something particular to my system. If push comes to shove, my guess is that the problem lay with the SC Pascal script.

I try to keep things simple in my simulator, and running multiple scripts for various panels through several interface cards doesn't exactly fit into this ethos.

It would be inaccurate to state that SC Pascal scripts don't work, because there are many enthusiasts who have them operating perfectly. But, I am not one of these individuals.

Note that I was using Sim Avionics. If using ProSim737 there is an option to use a script or direct drivers within ProSim737.

Quick List - Pros and Cons

PROS

Fairly accurate 1:1 ratio (or close to)

Easy to install and use software (knowledge of SC Pascal required if altering software)

Laser cut and stenciled lettering

Ethernet technology

CONS

Plastic shafts on ADF-ANT knobs (should be metal/stainless)

Poor quality knobs and switches on ADF, ACP and Rudder Trim module

Average light coverage for LED backlighting

ADF and ATC modules don't drop directly onto DZUS rails; the rails must be cut.

Large number of cards needed for operation

Not DZUS complaint (requires existing holes to be enlarged)

Plastic backing plate on panels (easily damaged when enlarging holes for DZUS fasteners)

Light seepage around edge of some panels from backlighting (no light skirt)

SC Pascal script troublesome and works intermittently.

Poor quality paint work

Considering the above, the panels are expensive.

Final Call

The modules are ideal for the budget-conscious flight simmer. This said, a potential user must have knowledge to troubleshoot problems.

The lack of quality knobs, switches and poor attention to detail detract aesthetically, while the large number of cards that need to be installed can make installation challenging. Three failing LEDS and problems with the frequency selector switch on the ADF radio panel may point to quality assurance issues. The use of Ethernet over USB is highly commended and may reduce information bottlenecks.

My rating for the software is 4/10 (The supplied scripts didn't work with my system, which at that time was Sim Avionics and not ProSim737).

My overall rating for the modules is 3/4/5-10 (based on fitting issues, quality of knobs, poor attention to detail, poor painting, no light skirts and temperamental frequency selection switches on ADF).

Please note that this review is my opinion only and is not endorsed.

POST SCRIPT: - July 15, 2012 - RETURNED MODULES TO SISMO REQUESTING REFUND

I have returned all the panelss, cards and wiring o SISMO for a full refund (minus freight).

Initially, SISMO offered me 10% of the value of the products purchased (this included the interface cards that had never been used).

SISMO stated that the return period had been exceeded, and any products returned would be treated as second hand units. It didn’t matter that SISMO had not, at that time, sent all the appropriate SC Pascal scripts to ensure correct operation of the modules.

The writing of the SC Pascal scripts was delayed close on 2 months after I received the modules, and when received, the scripts didn't funcyion as intended. Excuses were; staff holidays, workloads, Easter break, and awaiting confirmation from another company to facilitate operation.

Upon receipt of the returned items, SISMO claimed that many of my issues were incorrect or not relevant.

They claimed that the modules had been damaged.

They stated that I had broken the LEDS (I told them the LEDS were not working when I received the parcel).

They claimed I had disassembled the units and damaged the paint and screws.

They claimed I had re-painted portions of the units.

They claimed sticky plaster was attached to one of the units. (this is correct as I used tape to secure the wiring & also to create a trial light skirt)

They deducted from my refund, Spanish import duty and inspection fees (returned the goods to Spain).

They claimed I did not include paperwork (which I did).

They stated that as the ATC RADIO module was discontinued, a refund was not possible. At the time of purchase they did not inform me this panel was discontinued.

I'm not going to go into a long account to what has transgressed. But, I will say that this company cannot be trusted…..They promise the world to you, but if you aren't happy with the products, they provide every excuse possible to NOT provide an adequate and reasonable refund.

For example, when I reported the failure of the LEDS to SISMO, their response was 'they worked when they left the shop'. They did offer to replace the LEDS but, at my shipping expense (which was expensive). They also offered, because of the inconvenience caused, a discount on further purchases.

It should also be noted, that in my initial correspondence with SISMO, I asked whether their panels would drop directly into an OEM B737 center pedestal. Juan Ma stated 'YES'. However, on receipt it was discovered that the modules were too large to fit directly onto the pedestal DZUS rails. I queried Juan Ma from SISMO on this; he stated that it was a language misunderstanding.

Juan Ma understood perfect English when it came to avoiding a refund of purchase money.

Legislation, PayPal and Delays

Spanish legislation states that every purchase has a 7 day cooling off period, in which a return and refund can be made. PayPal policy states you have 45 days in which to make a claim. EU legislation states that refunds are possible if items do not function correctly - within a set time frame.

Without a working script for Sim Avionics (which took two months to receiveve), how can testing of panels occur. Because of the approximate two month delay on sending operating scripts to me, all options available to me had expired.

I cannot help but think that SISMO delayed the sending of the scripts so as to provide a reason for NOT refunding 100% of the purchase price.

SISMO Solicones appears to be a company that will ONLY support and stand by their products if you continue to use their products and not complain, or attempt to return them.

If you ask for a refund due to faulty components, components that don't function, or scripts that don't function correctly, then expect NOTHING, or at the very least, a minimal refund (and you will have to fight to get this refund).

What you can expect from SISMO, is e-mail after e-mail informing you that you have no right to a refund, that you have damaged the items, and that you did not follow SISMO policies, etc, etc.

After many e-mails, I succeeded in gaining a E400 Euro refund for an initial E1400 Euro outlay.

I'm sure there are many happy customers using SISMO products; however, I am not one. I do not recommend SISMO Solicones.

Their products are of poor quality. The attention to detail that is required (and expected) when replicating an aircraft panel is very poor. And finally, their customer service is dismal if you are seeking to return an item.

In my opinion, it's VITAL that a company standby and support their product-line, and this includes refunds if the product (for whatever reason) is not suitable with your simulator set-up.

If you search the Internet, you will find very few comments regarding SISMO, other than company endorsed reviews on forums that are supported by manufacturers and resellers.

If you are searching for quality avionics panels, look no further than Flight Deck Solutions or CP Flight.

These two companies are reliable, produce quality products and provide exceptional after sales service. They also offer a refund if not 100% satisfied with their product. Whatever you do, don’t spend your money on inferior products from SISMO! (my opinion only).

Feel welcome to make comments, either good or bad in the comments section.

Updated and Amended 15 April 2020

Update

on 2015-08-27 00:15 by FLAPS 2 APPROACH