it’s best to leave them attached, as removing the steering mechanism and associated equipment is a complicated and timely operation.

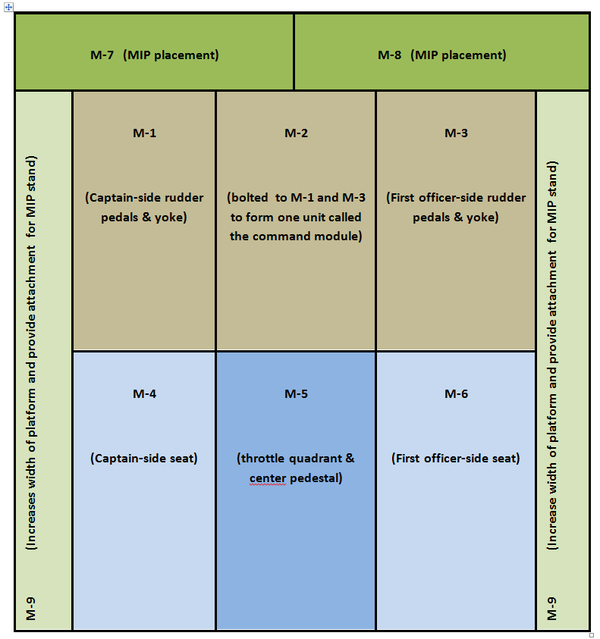

Behind the forward command module are three secondary modules to allow attachment of the two Weber seats and throttle quadrant. The MIP is attached to two smaller and narrower modules bolted at the front of the command module; whilst at each side two longer and narrow modules provide side support.

Platform Height and Dimensions

The height of the platform measures 16 cm (6.3 inches) and the total weight, including the two rudder pedals, internal mechanisms and control columns is approximately 160 kilograms (353 pounds). At this weight, it certainly will not be sliding anywhere.

The platform is not a full size platform as space availability at the current time is limited, however, if and when I wish to move into a full size platform, it will be easy to incorporate and bolt additional correctly sized modules to the existing structure.

Installing Weber Seats

The Weber seats need additional support as seat movement can generate stress at the connection point of the claw feet and floor. To ensure the seats fitted securely and any stress of seat movement was absorbed by the platform and not just the floor structure, the claw feet bolt directly through the floor to the aluminium tubing structure. Therefore, the platform absorbs the stress when the seats are moved rather than the flooring.

Platform Floor - ABS Plastic

In the real aircraft the floor is made from pressed aluminum which is studded (rivets) in strategic locations to ensure it is solidly fixed. Various hatches (hinged and otherwise) are present in certain areas to facilitate access to areas beneath the sheeting.

Builders use many different products for the floor, ranging from MDF fibreboard, ply and aluminium to tin or plastic. I was intending to use thin aluminium sheeting as a platform floor, however, when I discovered the price I decided to use something less conventional.

A supply of heavy duty ABS plastic was readily available; the advantage of this material being it doesn’t require painting as it’s already coloured Boeing grey, is easy to cut and work with, is of a thickness and weight that can withstand the intended weight and finally, doesn’t flex. Rather than use one large sheet of board for the platform cover, which would be unmanageable, the sheet has been cut to fit each corresponding module. The sheets are attached to the aluminium tubing of the module by normal stainless screws. If the material doesn’t hold up to my expectations, I’ll replace it with aluminium or quality ply board.

Although the ABS plastic is coloured grey, I found it to be too shinny in appearance. Preparing the ABS plastic for painting was straightforward and entailed thoroughly cleaning the plastic with detergent to remove any residue oil. Then the plastic was lightly scoured using a low grade sandpaper. This creates a suitable texture for the paint to adhere. The ABS sheeting was then painted with one coast of epoxy plastic primer and two coats of matt Boeing grey.

The ABS plastic and paint has held up to use very well. Even after scuffing, and moving the throttle quadrant onto and off the floor several times the paint and plastic has not been damaged.

One downside of using ABS plastic can be electrostatic discharge. If you wear socks on the platform and rub your feet on the ABS plastic a charge can build-up. I have yet to discover a way to stop this from occurring (other than wearing shoes).

Perhaps I will upgrade the ABS floor at some stage to a full aluminium floor, but at the moment I am more than content with the use of ABS plastic.